STA Universe Group is a high-tech and global engineering Group with about 3500 employees with a strong commitment to enhancing customer productivity, profitability and safety.

Our operations are based on unique expertise in materials technology, extensive knowledge about industrial processes and close customer cooperation. This combination, coupled with continuous investments in research and development (R&D), has enabled us achieve world-leading positions in the following areas:

Heating elements: Silicon carbide SiC heating elements, Molybdenum disilicide MoSi2 heating elements, Ceramic fiber heating module, Metallic heating elements, etc.

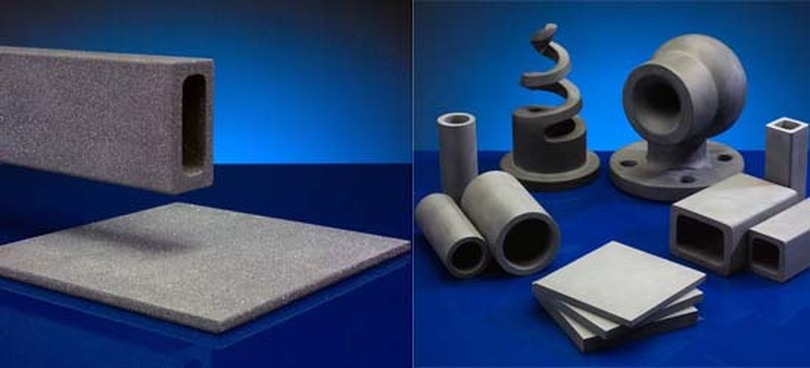

Special ceramic: Alumina ceramic, SSIC ceramic, Zirconia ceramic, Silicon nitride ceramic, Boron nitride ceramic, Boron carbide ceramic

Refractory material: Recrystallized SiC, Si3N4 bonded SiC, SiSiC, Silicon carbide, Sialon, Aluminium Titanate, SiC crucible, Graphite, Refractory brick.

Ceramic fiber: Ceramic fiber board, Ceramic fiber blanket,Ceramic fiber module, Ceramic fiber bulk, Ceramic fiber paper, Zirconia fiber board

Special metal alloy: FeCral alloy, NiCr alloy, Molybdenum.

Furnace: Muffle furnace, Tube furnace, Vacuum furnace, Atmasphere furnace, Dental furnace, Crucible furnace, Bottom loading furnace, Bogie hearth furnace, Oven, Tunnel kiln

STA’s operations are organized into three business areas responsible for research and development (R&D), production and sales of their respective products. Read more about STA's business areas