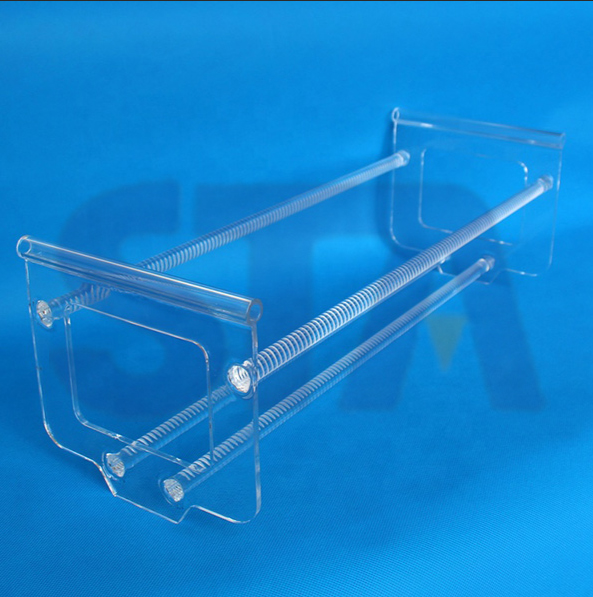

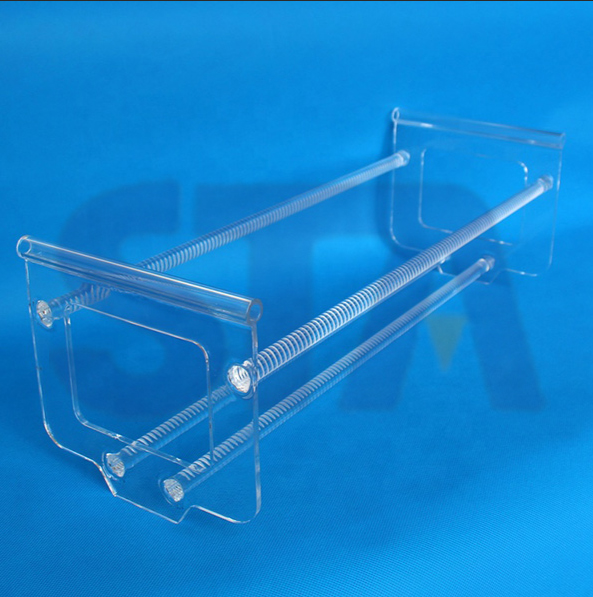

silicon carbide (SiC) wafer boat is typically made from a high-purity form of silicon carbide. It is designed with slots that can hold the wafers in place to prevent the wafers from sliding around during processes.

We offers customized silicon carbide (SiC) wafer boat. It is typically made from a high-purity form of silicon carbide. It is designed with slots that can hold the wafers in place to prevent the wafers from sliding around during processes. Manufacturing with hard and durable material, the SiC wafer boat can withstand high temperatures and chemical exposure. Our Silicon Carbide Wafer Boat, features extremely high purity (up to 99.99%), excellent plasma resistance and heat resistance, and restricted particle occurrence. It is used in various semiconductor manufacturing processes, including crystal growth, diffusion, ion implantation, and etching. They are an important tool for ensuring the quality and reliability of the wafers. It is widely used in equipment for semiconductor fabrication, industrial machinery, spare parts, etc.

Silicon carbide (SiC) boats play a crucial role in crystal growth furnaces, where they serve as carriers for the raw materials or seed crystals. Due to their exceptional thermal stability and chemical inertness, SiC boats can withstand the extreme temperatures and harsh environments typically encountered during the crystal growth process. This makes them ideal for use in furnaces dedicated to growing high-purity single crystals, which are essential for various advanced applications, including electronics and optoelectronics.

The silicon carbide (SiC) boat has a significant connection with the semiconductor furnace chamber. In semiconductor manufacturing, the semiconductor furnace chamber is a crucial component for various processes. The SiC boat, due to its unique properties such as high - temperature resistance and low reactivity, is used within the chamber. It is often used to hold semiconductor wafers or precursors during processes like annealing or epitaxial growth. The SiC boat can withstand the high - temperature and corrosive environment inside the chamber. Moreover, it helps in maintaining the stability of the wafers or materials being processed, contributing to the overall quality and performance of semiconductor products.

Specifications

Index | Unit | Value | ||

Material Name | Reaction Sintered Silicon Carbide | Pressureless Sintered Silicon Carbide | Recrystallized Silicon Carbide | |

Composition | RBSiC | SSiC | R-SiC | |

Bulk Density | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

Flexural Strength | MPa (kpsi)

| 338(49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

Compressive Strength | MPa (kpsi) | 1120(158) | 3970(560) | > 600 |

Hardness | Knoop | 2700 | 2800 | / |

Breaking Tenacity | MPa m1/2 | 4.5 | 4 | / |

Thermal Conductivity | W/m.k | 95 | 120 | 23 |

Coefficient of Thermal Expansion | 10-6.1/°C | 5 | 4 | 4.7 |

Specific Heat | Joule/g 0k | 0.8 | 0.67 | / |

Max temperature in air | ℃ | 1200 | 1500 | 1600 |

Elastic Modulus | Gpa | 360 | 410 | 240 |

Related products

We offers customized silicon carbide (SiC) wafer boat. It is typically made from a high-purity form of silicon carbide. It is designed with slots that can hold the wafers in place to prevent the wafers from sliding around during processes. Manufacturing with hard and durable material, the SiC wafer boat can withstand high temperatures and chemical exposure. Our Silicon Carbide Wafer Boat, features extremely high purity (up to 99.99%), excellent plasma resistance and heat resistance, and restricted particle occurrence. It is used in various semiconductor manufacturing processes, including crystal growth, diffusion, ion implantation, and etching. They are an important tool for ensuring the quality and reliability of the wafers. It is widely used in equipment for semiconductor fabrication, industrial machinery, spare parts, etc.

Silicon carbide (SiC) boats play a crucial role in crystal growth furnaces, where they serve as carriers for the raw materials or seed crystals. Due to their exceptional thermal stability and chemical inertness, SiC boats can withstand the extreme temperatures and harsh environments typically encountered during the crystal growth process. This makes them ideal for use in furnaces dedicated to growing high-purity single crystals, which are essential for various advanced applications, including electronics and optoelectronics.

The silicon carbide (SiC) boat has a significant connection with the semiconductor furnace chamber. In semiconductor manufacturing, the semiconductor furnace chamber is a crucial component for various processes. The SiC boat, due to its unique properties such as high - temperature resistance and low reactivity, is used within the chamber. It is often used to hold semiconductor wafers or precursors during processes like annealing or epitaxial growth. The SiC boat can withstand the high - temperature and corrosive environment inside the chamber. Moreover, it helps in maintaining the stability of the wafers or materials being processed, contributing to the overall quality and performance of semiconductor products.

Specifications

Index | Unit | Value | ||

Material Name | Reaction Sintered Silicon Carbide | Pressureless Sintered Silicon Carbide | Recrystallized Silicon Carbide | |

Composition | RBSiC | SSiC | R-SiC | |

Bulk Density | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

Flexural Strength | MPa (kpsi)

| 338(49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

Compressive Strength | MPa (kpsi) | 1120(158) | 3970(560) | > 600 |

Hardness | Knoop | 2700 | 2800 | / |

Breaking Tenacity | MPa m1/2 | 4.5 | 4 | / |

Thermal Conductivity | W/m.k | 95 | 120 | 23 |

Coefficient of Thermal Expansion | 10-6.1/°C | 5 | 4 | 4.7 |

Specific Heat | Joule/g 0k | 0.8 | 0.67 | / |

Max temperature in air | ℃ | 1200 | 1500 | 1600 |

Elastic Modulus | Gpa | 360 | 410 | 240 |

Related products