Molybdenum disilicide MoSi2 Heater are used in electric furnaces to deliver heating at temperatures as high as 1850 ºC. Used in production furnaces, Molybdenum disilicide heating elements are available in a number of different configurations and available with custom design options.

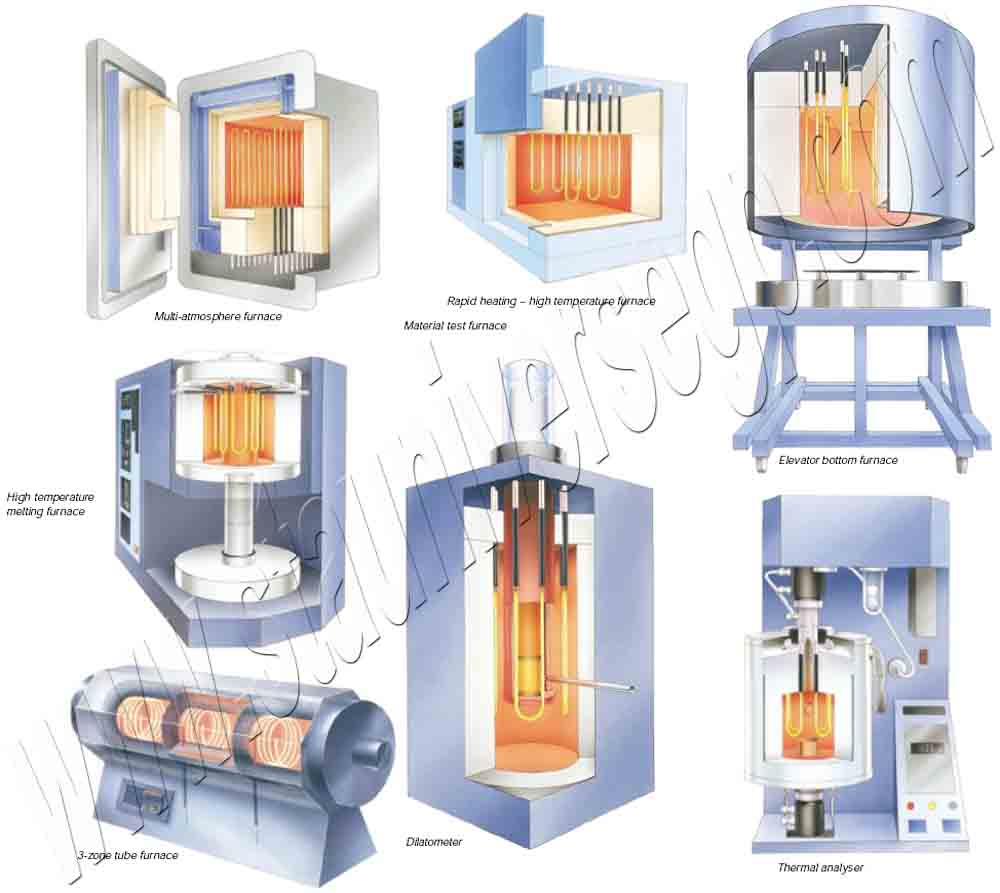

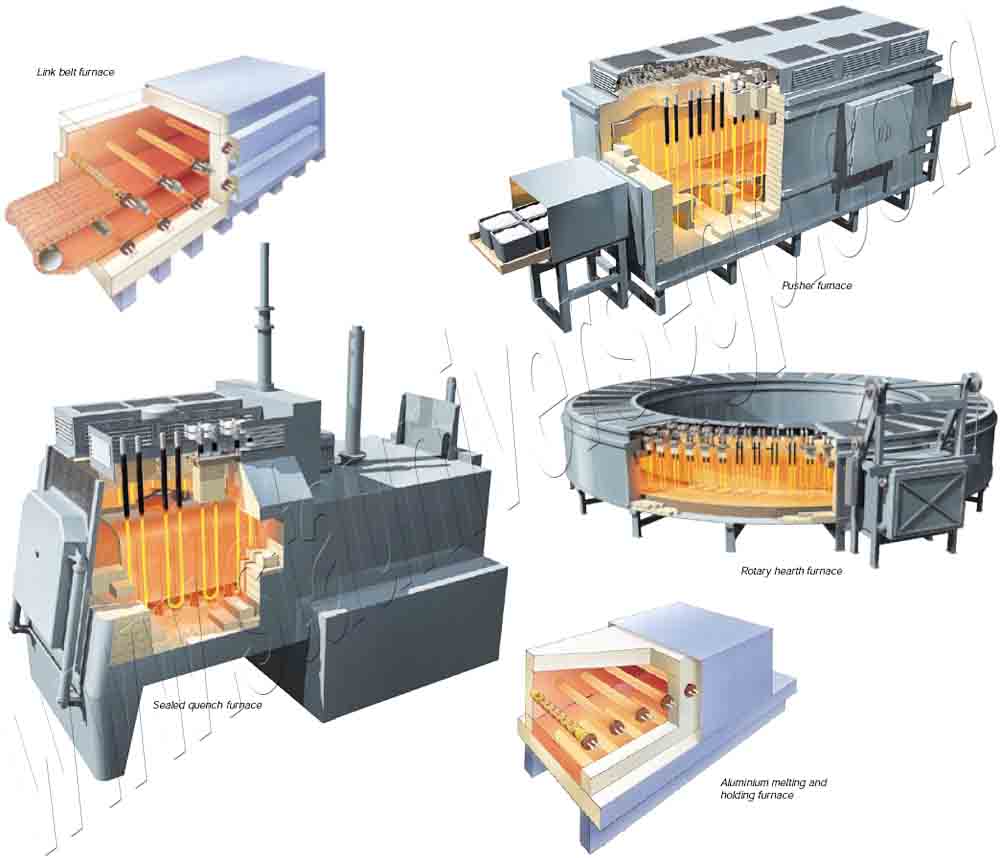

STA Molybdenum disilicide MoSi2 Heater are used in electric furnaces to deliver heating at temperatures as high as 1850 ºC. Used in production furnaces, laboratory equipment, glass melting and many other applications, Molybdenum disilicide heating elements are available in a number of different configurations and available with custom design options to meet the specific needs of your facility or operations.

Unique properties of MoSi2 heater

Molybdenum disilicide elements may be used up to a surface temperature of 1800ºC in oxidizing atmospheres.

Long service life and ease of replacement contribute to high furnace utilization and low maintenance costs.

New and old elements can be used together and in series.

Can dissipate high power loading.

Can be used continuously or intermittently.

Provide rapid furnace temperature ramping.

Grades of Molybdenum disilicide heating elements

TYPE 1700 Grade, Maximum Element Temperature – 1700°C.

General Applications, This molybdenum disilicide heater is Most used in industrial furnaces for heat treating, forging, sintering, glass melting and refining, and for use in radiant tubes.

TYPE 1800 Grade, Maximum Element Temperature – 1800°C.

General Applications, This MoSi2 heater is widely used in Laboratory furnaces, testing equipment, and high temperature sintering production furnaces.

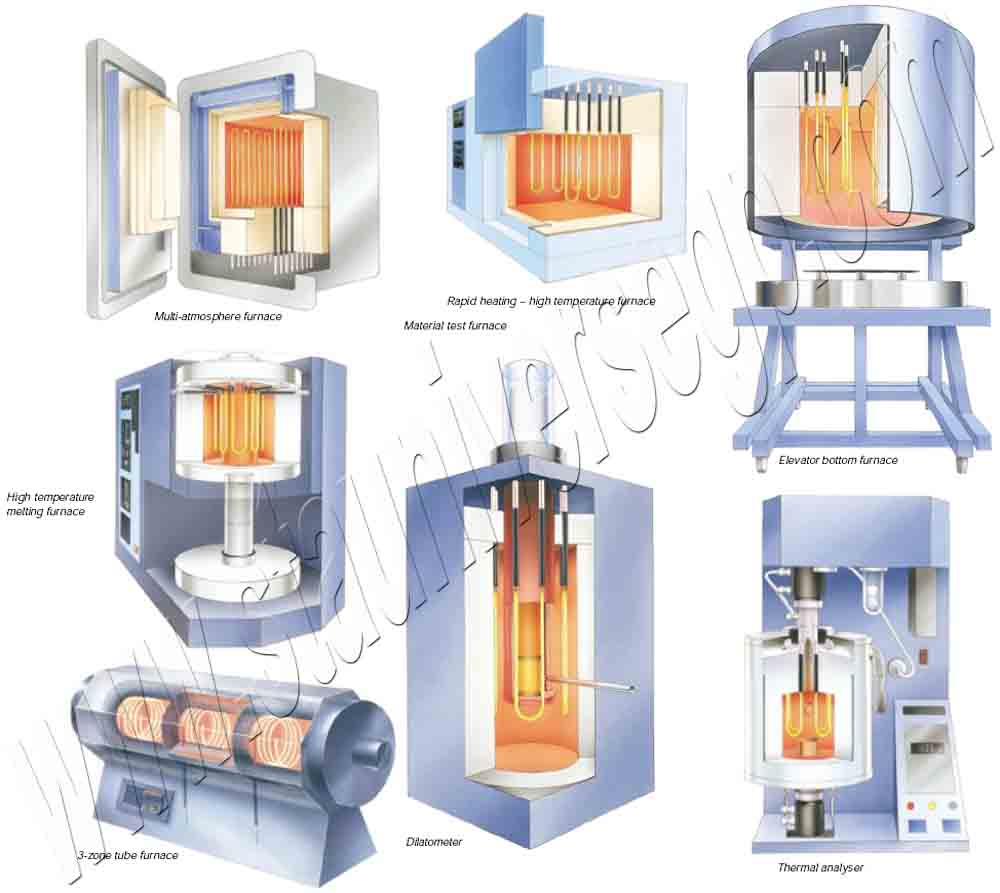

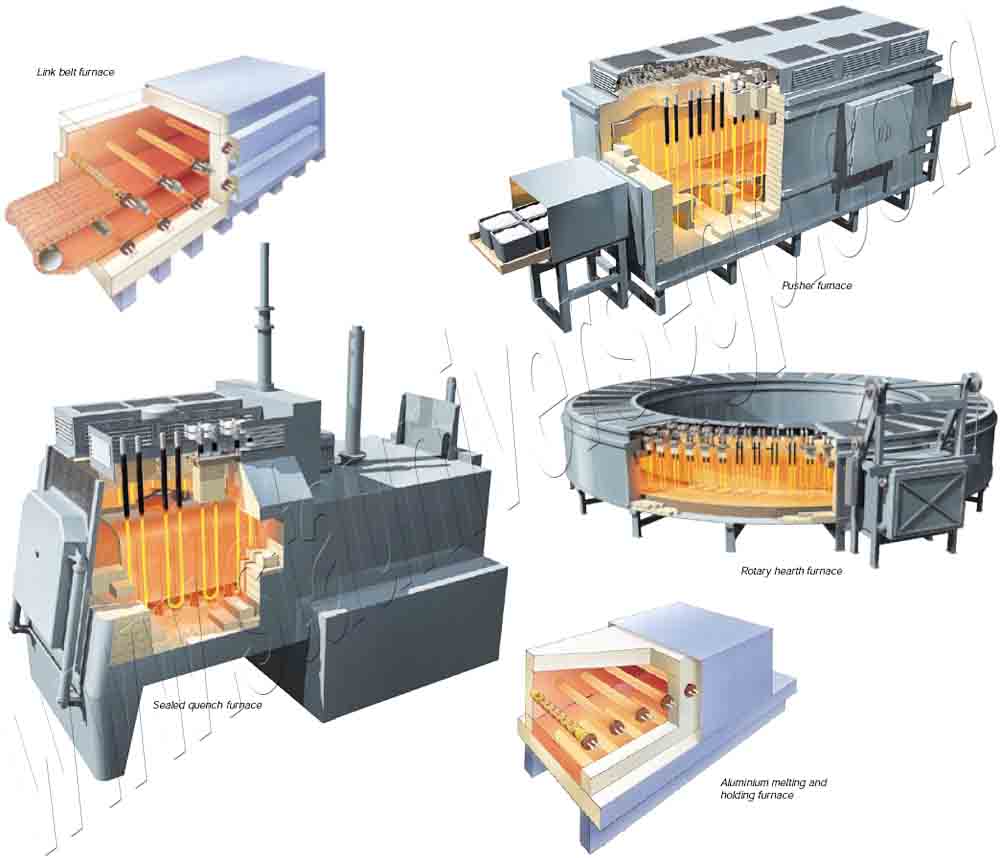

STA Molybdenum disilicide MoSi2 Heater are used in electric furnaces to deliver heating at temperatures as high as 1850 ºC. Used in production furnaces, laboratory equipment, glass melting and many other applications, Molybdenum disilicide heating elements are available in a number of different configurations and available with custom design options to meet the specific needs of your facility or operations.

Unique properties of MoSi2 heater

Molybdenum disilicide elements may be used up to a surface temperature of 1800ºC in oxidizing atmospheres.

Long service life and ease of replacement contribute to high furnace utilization and low maintenance costs.

New and old elements can be used together and in series.

Can dissipate high power loading.

Can be used continuously or intermittently.

Provide rapid furnace temperature ramping.

Grades of Molybdenum disilicide heating elements

TYPE 1700 Grade, Maximum Element Temperature – 1700°C.

General Applications, This molybdenum disilicide heater is Most used in industrial furnaces for heat treating, forging, sintering, glass melting and refining, and for use in radiant tubes.

TYPE 1800 Grade, Maximum Element Temperature – 1800°C.

General Applications, This MoSi2 heater is widely used in Laboratory furnaces, testing equipment, and high temperature sintering production furnaces.